Here we are nearly at the end of the second week of the new year and the weather is mild and pleasant, apart from the rain and gales. The great spotted woodpecker has started drumming in the nearby woods and the days are getting noticably longer by at least 15 minutes.

Getting Started.

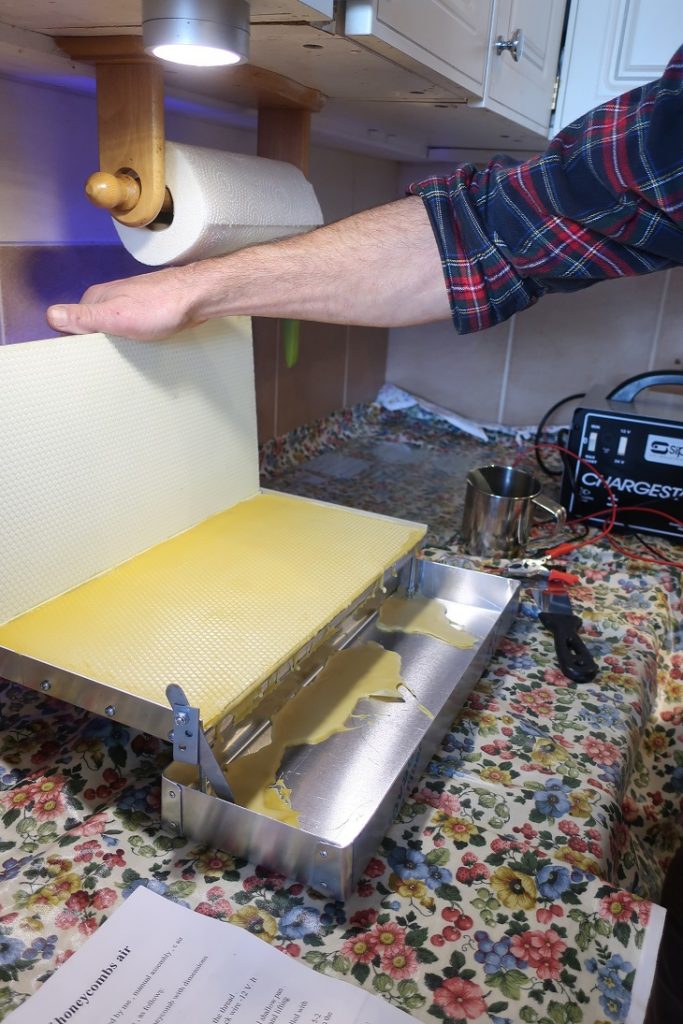

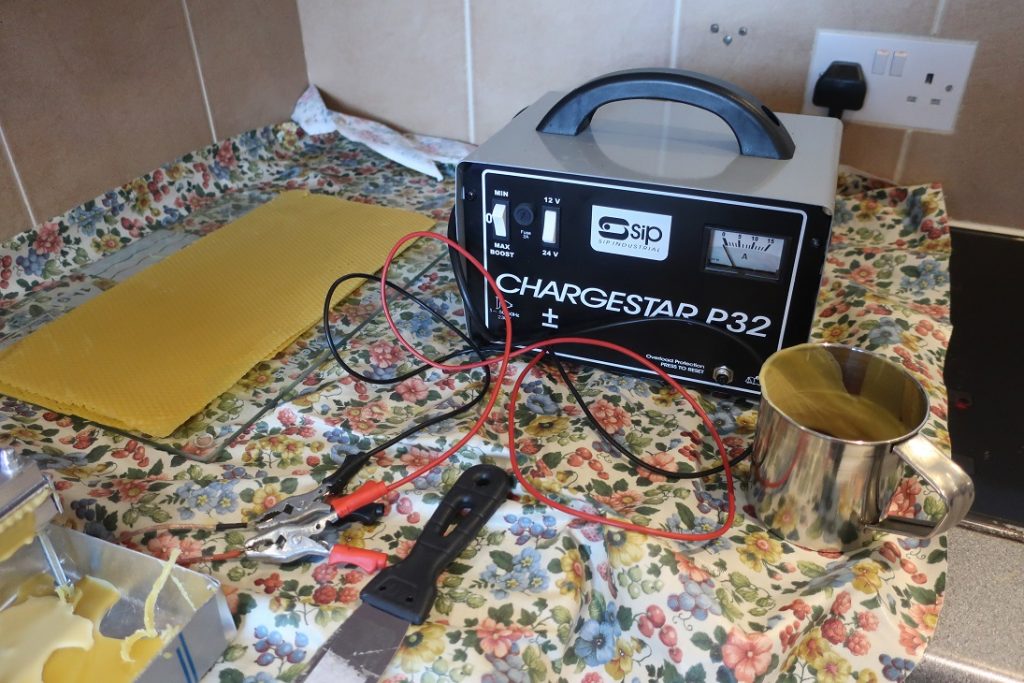

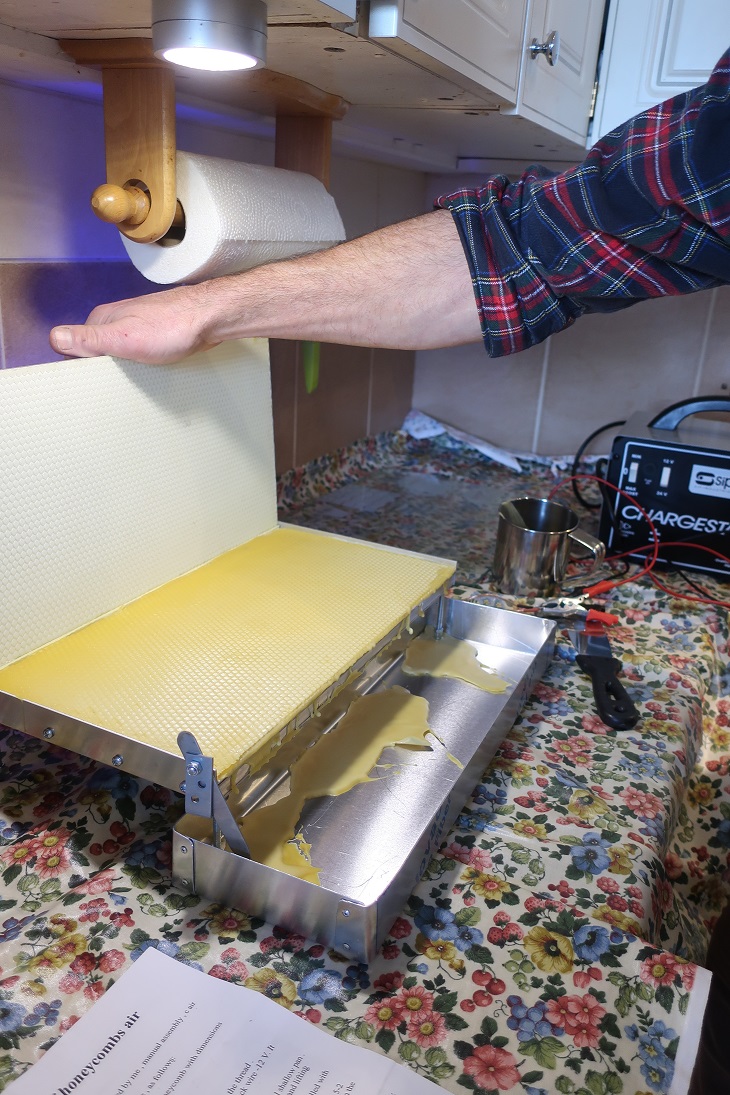

I’ve achieved a another goal which was to try out the foundation maker before Linton went back to work after the holidays. It involved attaching the cooling fan up to the car battery charger, but that is not as difficult as it first looked and turned out to be the easiest part of the process.

Making wax foundation with your partner is potentially stressful unless you’re both pretty patient. Traditionally we are advised not to take driving lessons with our nearest and dearest and this warning could equally apply to parts of beekeeping. The room filled with the soothing scent of beeswax but the air was blue with expletives.

I explained in a previous blog about the kit I bought online from Latvia on the recommendations of Fred from Dundee who did a great job making foundation with some of our wax a couple of years ago.

The written instructions that arrived with the kit were not so easy to follow as parts were lost in translation so we checked out a YouTube video and got the general gist. I heated the wax in a bain Marie which is a pot sitting on a pot of boiling water so that the wax is never in direct contact with the heat of the stove. Now that could cause an explosive fiery situation! Wax melts at ca.63.4 degrees Celsius but we heated it to 70 degrees C as per YouTube instructions. Later Fred tells me that it needs to be hotter at Ca. 80 degrees C, so perhaps that accounted for a lot of cracked frames.

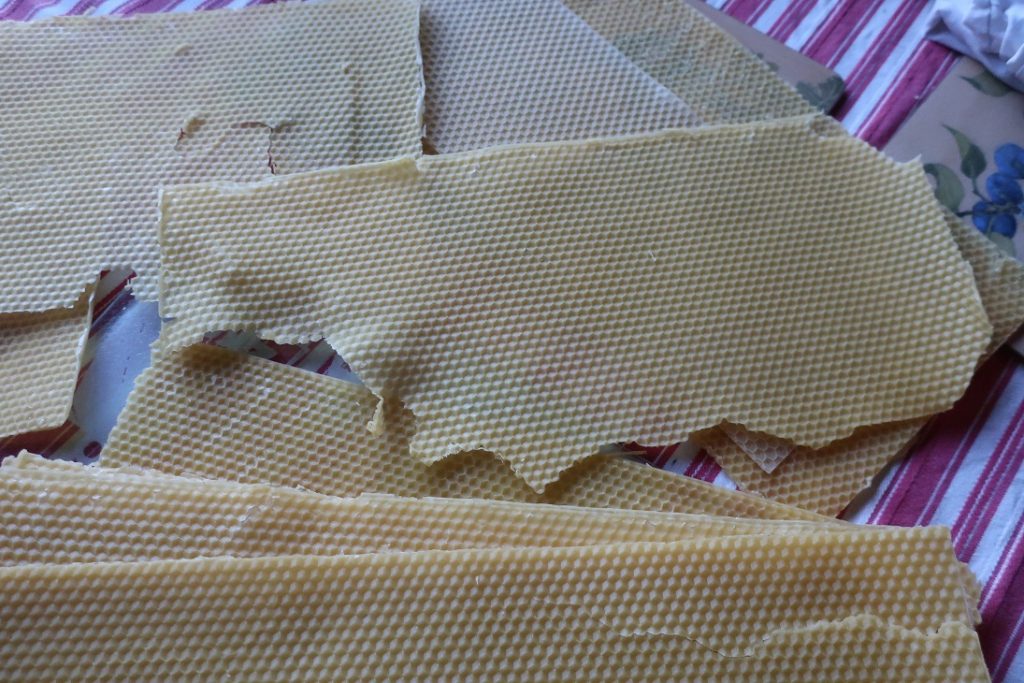

Using that little measuring cup on the right we poured in around 3/4 of a cup of hot wax evenly into the bottom part of the presss and closed the top lid which sent the excess wax into the tray at the front. We opened the press after 10 seconds then closed it again quickly as instructed to reduce adhesion. We were to wait 2-3 minutes before opening again and that was the tricky part. Even waiting the recommended time didn’t mean that the sheet of wax was going to come cleanly out of the tray. Many stuck fast and had to be scraped out and re- melted. We tried spraying food grade cooking oil in a water mix as a releaser and that helped a bit. Someone recommended a drop of washing up detergent in water, but as I want to use some of the foundation for cut comb I’m reluctant to use it. Making your own foundation is very time consuming but we did get a few frames made that afternoon.

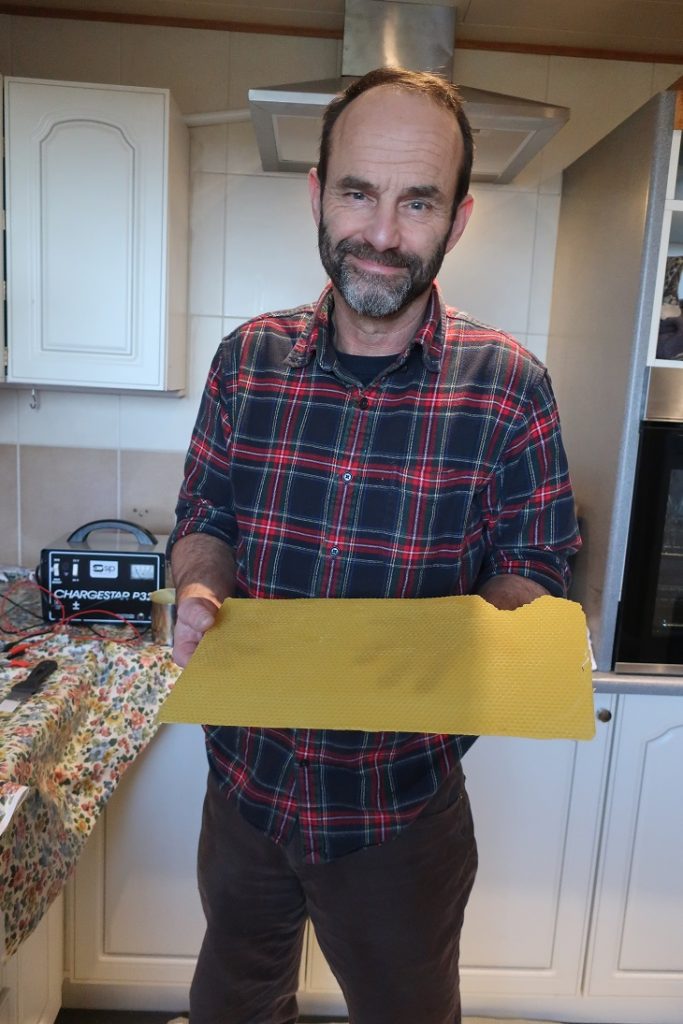

Beginner’s luck for Linton with the first frame almost perfect. The press is designed with dimensions for Langstroth frames so they need to be cut to size for our National frames. This means that I can use many of the sheets that are not perfect. I can cut up the thinnest when I make up sections or cut comb. Getting the foundation thin enough will be the next challenge when I try again soon. It is not nearly as messy as I thought it might be though. The biggest challenge was removing the sheets intact from the press. If you have plenty time for foundation- making then it could be quite enjoyable once you get into the swing of it but I can’t see many of my bee farmer friends doing it.

Having said that, I’m really pleased with our achievements and I guess “practice makes perfect” applies here. The next step is making up the frames before the season starts. I’m grateful to Linton for helping me get started with this project.

Latest News on Honey Bee Vaccine.

Some exciting news this week as Dalan Health announces that the first honey bee vaccine against American Foulbrood has received a conditional license from the USDA Centre for Veterinary Biologics in the US. Different states have different licensing laws in the US and it is not yet approved for use in the UK. https://www .dalan.com/ . It will be fed to the colony and the queen will obtain it through trophallaxis and pass it on to her offspring. It will also be passed on horizontally between workers. For a quick review of honey bee immunity you can read this previous post, Coping with Pests & Pathogens: Honey Bee Immunity. (beelistener.co.uk).

Great job Ann. I would suggest the wax melter that can be purchased from Amazon, as it is thermostatically controlled and fitted with a drain tap.

Thanks, Fred. That sounds like a good investment.

I wonder, Ann, have you tried skipping the use of foundation, and just putting an empty (but wired) frame between two frames filled with drawn comb? You will get combs that are a mix of worker and drone comb, but since this is what the bees have chosen to make, I consider it OK. And you can be sure that the wax in these combs is new and clean.

Well, just a thought about a way to save on your own labor, and to give you more wax for making beautiful candles. But I can see that making foundation is pleasing, and is a good use of the cappings wax gained when extracting honey.

Hello Tom. No, I hadn’t thought of doing that but if I get some stainless steel wire I will give it a go. Thank you for the tip as a good way to do it between two frames of already drawn comb. I wouldn’t have thought of that. Foundation making might be more pleasing as I get better and more successful but I cannot say I have reached that point yet.